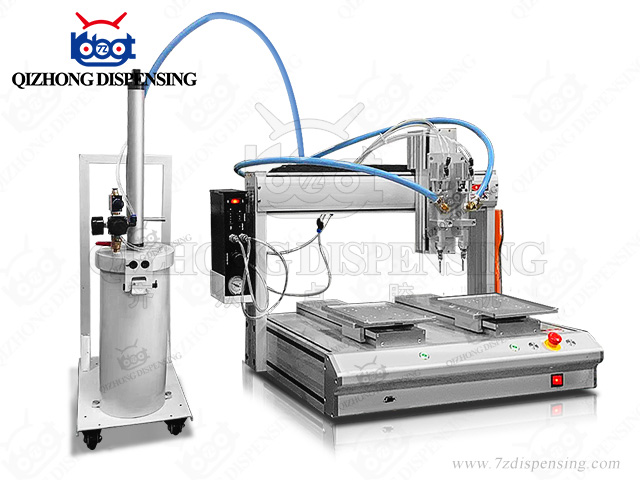

Dual Station Table Automatic Dispensing Machine With 2600ML Silicone Storage Tank QZ5331JT2600-BX

- Brand: Qizhong Dispensing

- Model: QZ5331JT2600-BX

- Origin: NingBo CHINA

- Shipping Terms: EXW/FOB/C&F

- Delivery Time: 5 work day (Except for customization)

- Service: Recommend suitable glue

- Experience: More than 10 years experience in dispensing industry

Introduction

The dual table robot eliminates part replacement and loading time, and the unique dual table design enables high-speed manufacturing. This can be accomplished by removing finished parts and loading new parts on a mixture of one workbench while the other is being handled by the robot. The dual table design provides users with the option to perform two different dispensing procedures in sequence.

keywords: Silicone-glue2600ML4-axisdouble-station

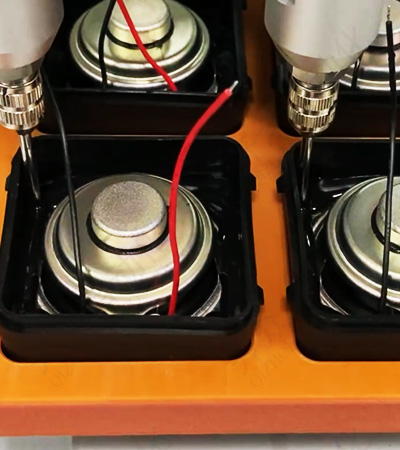

Gluing Effect

Gluing Video

Features

2. Double-station design: One-in and one-out double worktables make full use of the waiting time of the equipment during the product loading and unloading process, so that the equipment can exert the best working efficiency.

3. Precision glue volume controller for glue valve: After more than 10 years of stable application, the stability of the machine in glue volume control is guaranteed.

4. All-aluminum profile frame: The batch mold opening process ensures the consistency of the machine and the weight of the profile ensures the stability of the machine.

5. Hand-held programming teaching box: Any graphics track on the same plane can be edited by command methods such as point/line/arc.

Advantages To The Business

2. The equipment is equivalent to being a skilled worker from the beginning, and no longer worry about cultivating a skilled worker.

3. Solve the gluing process that cannot be achieved manually, and help break through the bottleneck of product process (such as product gluing precision, uniformity, consistency, etc.).

4. Help to improve the production capacity and quality of enterprise products, and can realize batch replication.

Technical Parameters

| MODEL | QZ5331JT2600-BX |

| Maximum Speed (X&Y/Z) | 500 x 300 x 300 x 100mm |

| Body Dimensions | 800 x 600 x 600mm |

| Weight | 60KG |

| Distance between Z-axis and worktable | 100mm |

| Workbench size | 200mm*150mm(W/D), M4 Hole Position, 40mm*40mm Spacing |

| Industrial Movement | X/Y1/Y2//Z 4 Axis |

| Drive System | Precision micro-stepping motor and Stepper drive |

| Transmission Method | Timing Belt/ Precision Linear Guides |

| Safety Protection | Photoelectric Sensor |

| Edit Programming | Handheld Programmer |

| Program File Name | Numbers and letters |

| Operation interface | Chinese (Simplified)/English, freely switchable |

| Interpolation Function | Point/line/line segment/arc/full circle/3D trajectory, etc. |

| Test | Separate Button |

| I/O Signals | 4 inputs / 4 outputs |

| X/Y1/Y2/Z Maximum Load | 10kg/10kg/10kg/3kg |

| Equipment Power | Less than 500W |

| Power Supply | AC220V±10%/AC,50/60Hz |

| Air supply requirements | 0.5~0.7Mpa, Dry air source |

| Environment Temperature | 0 ~40℃ |

Service

2. 24-hour online services.

3. Lifelong service of equipment best price replace parts.

4. Provide free gluing sample service before sale.

5. Recommended supporting automation process solutions.

Contact Us

Company Name: NINGBO QIZHONG AUTOMATION TECHNOLOGY CO., LTD

Mobile : +86-15869524628

Email : qzdispensing@163.com

Add : No. 3346

Qingshaoniangong North Road Cixi City Ningbo Zhejiang China