The Principle and Application of Piezoelectric Injection Valve of Automatic Dispensing Machine

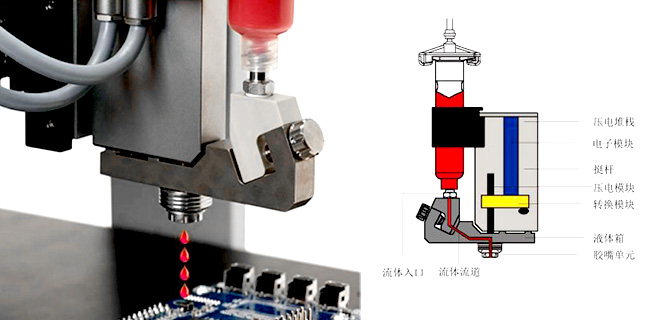

The piezoelectric injection valve of the automatic dispensing machine uses the characteristics of piezoelectric materials to generate mechanical force through voltage. When the piezoelectric material below is charged, the valve opens; when the piezoelectric material above is charged, the valve closes. Because the space for opening and closing the valve is extremely small and the operating frequency is extremely high, it can eject a very small amount of liquid material at high speed. The dispensing head keeps a certain distance from the substrate, and the glue liquid near the nozzle outlet is forced to obtain a large speed through the instantaneous high pressure, so as to separate from the nozzle, form droplets, and drop on the target position to achieve coating.

Features of piezoelectric jet dispensing valve for automatic dispensing machine:

1. Non-contact jet dispensing to achieve higher production efficiency of automatic dispensing machine.

2. High precision dispensing.

3. To achieve higher production efficiency, the glue spraying speed can conventionally reach 300 times per second.

4. Applicable to a wide range of fluid viscosity.

5. Precise modular design.

6. Convenient and quick cleaning.

7. There is no dispensing pollution, lead damage and chip scratches caused by the contact between the needle and the target surface in contact dispensing.

Jet valve application

Fluid dispensing technology is a key technology in microelectronic packaging. It can form dots, lines, surfaces (coating) and various patterns, and is widely used in surface mount adhesives, conductive silver paste, IC packaging glue, bottom Controlled flow and high-speed dispensing of various adhesives such as fillers, sealants, and surface coating adhesives. This technology precisely dispenses fluids in a controlled manner, transferring ideally sized fluids (conductive glues, epoxies, adhesives, etc.) to the appropriate location on the workpiece (chips, electronic components, etc.) Mechanical or electrical connection between devices. This technology requires good operation performance of the dispensing system, high dispensing speed, and good consistency and high precision of the dispensed dots. At present, both at home and abroad are researching glue dispensing equipment that can adapt to a variety of fluid materials and has better flexibility, so that it can precisely control the fluid flow and the position of the glue point, so as to obtain a uniform glue point, and at the same time realize the glue point. Accurate positioning to meet the needs of the development of the electronic packaging industry. With the development of the packaging industry, the dispensing technology has gradually changed from contact dispensing to non-contact (jetting) dispensing. In the past few decades, great progress has been made in the research of contact needle dispensing, which can achieve accurate positioning of the glue point and obtain glue points as small as 100 microns in diameter, but its dispensing speed is slow and the glue point is consistent. Poor; the emergence of non-contact jet dispensing greatly improves the speed of fluid material distribution, the jetting frequency is high, and the glue points are uniform and consistent.

Typical applications of piezoelectric injection valve for automatic dispensing machine:

Suitable for solder paste spraying, MEMS (Micro Mechanical Electronic System) packaging, UV materials for precision assembly, underfill, wafer bonding, conductive silver paste, paste in electronic packaging industry, lighting LED industry, energy industry, life medicine and other industries Dispensing applications such as film red glue, hard disk assembly, etc.

The automatic dispensing electromechanical jet valve is less limited by the glue, and is widely used in the production of droplets of low-viscosity and high-viscosity fluids, such as ink, liquid crystal, epoxy resin, etc. Taking the manufacture of liquid crystal displays as an example, for a 22in flat panel, it takes 2 days to use contact dispensing, while for non-contact dispensing, the working time is only 2 hours. Improved work efficiency.

keywords: CCD