Common sense of AB glue dispensing robot

AB glue dispenser, also known as double liquid dispenser, is named for the properties of glue. According to the characteristics of the glue itself, such as glue corrosivity, curing time, proportion, viscosity and glue amount, etc., it greatly affects the configuration of the glue dispenser equipment. AB glue dispenser, there are many extended products, such as AB double-liquid machine, AB glue filling machine, AB glue machine, etc., which are all auxiliary equipment of double-liquid glue dispenser evolved in different ways. AB glue is called two-component glue. Compared with the single-liquid glue dispenser, there will be one more glue storage device. The A glue storage bucket is used for this glue, and the B glue storage bucket is used for the catalyst. When the glue in bucket A and the catalyst in bucket B are conveyed by the air pressure or pump of the two-liquid glue dispenser to the two-liquid glue valve-three-way-mixing pipe automatic glue mixing, then the glue will be fully melted before curing.

Common AB glue types (two-component glue)

AB epoxy resin, AB polyurethane, AB silicone, PU adhesive, structural adhesive, etc.

Double liquid glue has the following characteristics:

1. Moisture-proof and dust-proof;

2. Oil resistance, water resistance, acid and alkali resistance;

3. High bonding strength;

4. Good toughness, high and low temperature resistance, heat resistance;

5. The cured product has electrical and physical properties, such as insulation and compression resistance;

AB glue dispensing machine double liquid glue precautions

Although AB glue has many properties and properties, there are still many precautions to keep in mind, such as:

1. Keep ventilation in the place where double liquid glue is used;

2. It is recommended to wear isolation gloves when using to avoid skin and eye contact;

3. It is not recommended to mix glue of different specifications;

4. When using, please ensure the correct mixing ratio to achieve the desired effect.

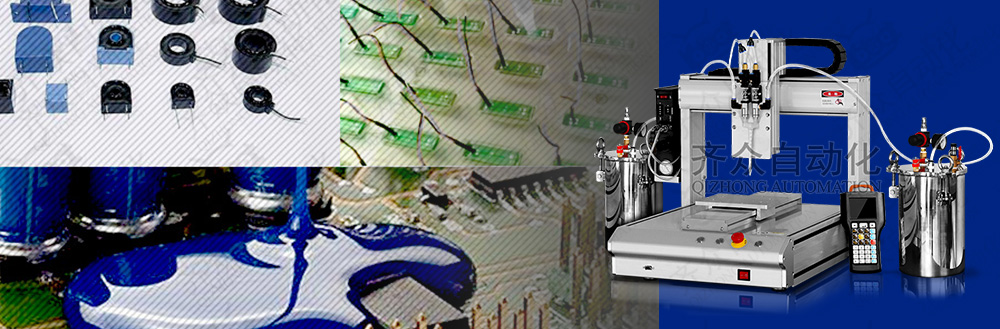

Common AB glue dispenser types

1. Gear pump, metering pump type high-precision AB glue dispensing machine, mainly used for AB glue dispensing with high ratio and high viscosity above 3:1, with high precision and accurate ratio.

2. The glue control system is equipped with a precision double-liquid dispensing valve type AB glue dispensing machine, which is mainly used for two-component glue with a ratio of less than 3:1. The ratio is adjusted by double-liquid glue, and there is a certain error value, but for conventional If the requirements are not high, it can be ignored.

Application field of double liquid dispensing machine equipment

Two-liquid dispensing machine is mainly used in power supply potting, capacitor potting, LED module potting, LED energy-saving lamp potting, transformer potting, sensor potting, automotive ignition coil potting, PCB integrated circuit board potting, semiconductor potting Packaging, PCB electronic parts fixing and protection, mobile phone, notebook shell bonding, LCD glass substrate packaging, LED dispensing, optical lens dispensing and packaging, auto parts coating, chip bonding, hardware parts coating and bonding Connection, battery packaging, speaker dispensing, quantitative liquid filling and other processes!

Two-liquid dispensing machine equipment maintenance method

After each work is completed, it should be cleaned in time, and it should be cleaned. Otherwise, the glue will solidify and block the valve, and the glue will not come out when the glue is dispensed next time. If it is not cleaned, the next time you use another kind of glue to inject glue, it will cause a variety of glues to be mixed, and then there will be a series of phenomena such as the glue of the product that you point out does not dry, and the quality of the product has problems!