Applications

Tool Box Bonding Sponge Pad

2022-07-03 17:37:42

In fact, the principle of the double-head glue dispenser is the same as that of the single-head glue machine, but some improvements have been made on the basis of the original single-head glue machine. The single-head glue dispenser is that each controller controls the glue dispensing of one dispensing needle, while the double-head dispensing machine is improved to one controller to control the glue dispensing of two or more needles.

Advantage

The original intention of the double-head glue dispenser is to improve production efficiency and save costs for enterprises. Two dispensing heads can work at the same time (equivalent to two identical dispensing machines working at the same time), or a single head can be set to work as needed.

How to operate

The program setting is also very simple. You can set a relatively simple program through the touch screen of the machine, and also support the CAD function. You can download the CAD drawing on the computer to the machine, and let the machine generate the program by itself. Running on the track of the CAD drawing is both convenient and accurate.

The main purpose

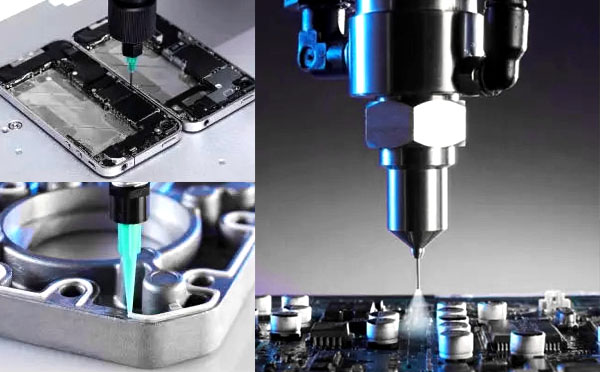

Common applications include: automotive mechanical parts coating, mobile phone button dispensing, mobile phone battery packaging, notebook battery packaging, coil dispensing, PCB board bonding and sealing, IC sealing, speaker outer ring dispensing, PDA sealing, LCD Sealing, IC packaging, IC bonding, chassis bonding, optical device processing, mechanical sealing, etc.

Applicable fluids: silicone, EMI conductive adhesive, UV glue, AB glue, quick-drying glue, epoxy glue, sealant, hot glue, grease, silver glue, red glue, solder paste, thermal paste, solder mask, clear paint , screw fixative, etc.

Main uses: bonding, pouring, coating, sealing, filling, dripping, linear/arc/circular gluing, etc. in the product process.