Applications

Horn, speaker, buzzer, sound shell coated with yellow glue

2022-07-11 18:06:21

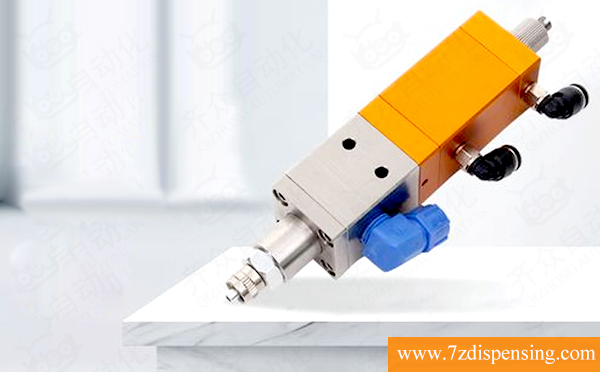

Speakers, speakers, buzzers and sound shells can be glued using a three-axis glue dispenser. Yellow glue is often used as the bonding glue. Due to its relatively low coagulation and cost, it will not affect the sound, which is especially suitable for sound generator products. For dispensing, it is recommended to use a three-axis dispensing machine, mainly to control the cost and the type of machine.

Loudspeaker gluing process

Applying yellow glue to the loudspeaker is mainly to bond the loudspeaker and the shell together. It is easy to fall off by screwing, because the loudspeaker is often vibrated, and the vibration is prone to loosening of the screws. The glue coating method can also be used to achieve sealing. The engineering process: Place the speaker on the Y-axis of the three-axis glue dispenser platform, and the Z-axis is glued according to the set path to ensure that it is completed as required.

Loudspeaker gluing requirements

The loudspeaker is a combination of a horn, a plastic casing and a circuit board. The loudspeaker is closely attached to the plastic casing. In order to maintain the appearance and practicability of the loudspeaker, the bonding can be fixed and the occurrence of noise can be avoided. The problem of fixing the speaker, the glue application technology is mature, it is not easy to have the problem of dispensing, and the production is very smooth.

yellow gum

Yellow glue, also known as universal glue, is often used to bond plastic and metal or plastic and wood. The glue will not solidify inside the pressure barrel at room temperature. It needs to be exposed to air to solidify. There is no need to clean and dispense the glue during the speaker gluing process. Valve, you only need to replace the dispensing needle, which is a very convenient glue.